Case Study: The Dorman OE FIX Guide

The Challenge

Not long after I joined Dorman Products, leadership asked my team to reevaluate the value of a glossy print catalog called the Service Dealer Guide that we had been producing in largely the same format for nearly 20 years. Dorman released thousands of new auto parts every year, and this publication was initially created to help raise awareness of the most popular and useful new products we had available. Was it working? Was print still necessary in 2018? Could we save money and achieve similar results with a digital-only solution?

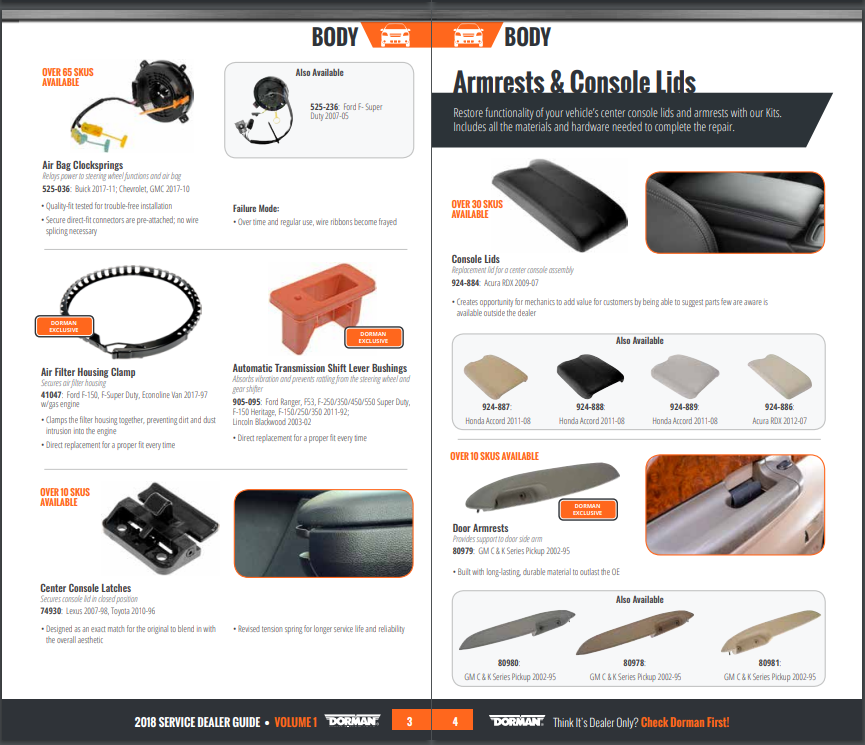

From a design perspective, the publication was pretty standard fare for the automotive aftermarket - a collection of widgets and bullet points. Below’s a sample spread from the edition that was published shortly after I started. We printed approximately 1 million of these and distributed them through our retailers and distributors across the United States and Canada.

Meanwhile, Marketing was also challenged with how to convince mechanics - the primary users of the auto parts we manufactured - that we were more than just another generic parts brand. This basic catalog of parts didn’t do much to tell our impressive engineering and innovation stories.

The Strategy

The path of least resistance moving forward would’ve been to simply create a digital-only version of the catalog. By eliminating printing altogether, that would’ve given leadership the cost-savings they were after, while giving other internal stakeholders what they were used to. (It probably would’ve even scored some points by making us look forward-looking by going digital-first.)

But we weren’t just trying to save money - we were trying to grow market share and build our brand.

So, rather than simply change the format and distribution method, my team started building a new strategy from scratch. We developed customer personas to better segment which members of our audience wanted what type of information at various points in the buyer journey. We went on field visits to distributors, parts stores, and auto repair shops to ask questions and gather feedback. We looked at what the competition was doing, as well as looked at best practices from other manufacturers in other industries.

One thing that was clear from our conversations was that print was still a sought-after format in this field. Mechanics work on corroded vehicle components all day, and many did not want to cover their phone touchscreens with grease and grime. Even those auto repair professionals who worked behind a counter or at a desk mostly used various closed software systems and electronic cataloging systems to search for products, with much of the Internet blocked from browsing by internal filters. That seemed to pose some challenges with getting the content in front of our target audiences if we went exclusively digital.

In fact, we knew from our research that many other brands had cut back on their print budgets over the years, likely for the same cost-saving reasons our leaders were exploring. What if sticking with print actually represented an opportunity given reduced competition in the mailbox, a smart zig while everyone else was zagging?

That led us down the route of continuing with a print publication, but rethinking everything else about it - the look, the content, the distribution, the measurement. What if we created something that mechanics actually wanted to pick up, read, share with their colleagues, and keep around the shops for months or years to come? What if we reduced the quantity, but were more surgical in our approach to make sure we got it in the hands of our highest-value customers?

We determined that what our audience most needed was greater insight into how to solve the problems they were encountering. Content that would actually allow them to work more efficiently and cost-effectively would be well worth their limited time. Fortunately, our subject matter experts had this information readily available because they had to evaluate different vehicle problems to develop some of our most innovative products. By just documenting and sharing the back stories to some of these products we could better enable mechanics to diagnose problems on their customers’ vehicles, which would also conveniently steer them to our products as the ideal solutions.

The result was the OE FIX Guide, a premium magazine that told the stories behind our line of OE FIX products. In automotive parlance, OE refers to original equipment, i.e. the parts and components that make up the vehicle when it rolls off the assembly line. Dorman OE FIX parts are meant to solve problems with the original components, and by focusing on the stories of how we did that we could showcase our ingenuity and engineering prowess.

We also knew that the medium is the message. Rather than just telling our readers we were different, we needed to show them, and trying to convey innovation with the same old format would make the message feel partly hollow. Instead of going with the glorified pamphlet of years past, our design team created a larger format publication filled with original lifestyle photography that felt more like a subscription magazine than a product catalog.

Best of all, we found we could create a better magazine while still reducing costs significantly just by being smarter about production and distribution. Utilizing a mix of first-party and third-party data we gathered from multiple sources, we were able to put together a more targeted distribution plan that incorporated a mix of direct mail and channel partner distribution. That allowed us to dramatically reduce the number of copies we printed while significantly increasing the number that made it to our intended audience - a win for all stakeholders.

The Results

OE FIX Guide Vol. 1 was released in early 2019, immediately receiving rave reviews from customers, and eventually winning an award from the Content Marketing Institute for best transportation-related publication, beating out other finalists including Mercedes-Benz, Volvo and WestJet. Our Sales team was also able to leverage the publication to secure hundreds of thousands of dollars in additional distribution for products featured in the guide.

Mission accomplished, right? While we were thrilled with the results, we knew our team was capable of more, and with each subsequent edition we added more editorial content while further fine-tuning our distribution.

With OE FIX Guide Vol. 3 we began incorporating a QR code to a survey, sending respondents free Dorman swag in exchange for telling us how they received the guide, what they liked about it, and what they’d like to see more of in the next edition.

We received hundreds of responses from mechanics and parts store professionals, including at least one response from every U.S. state, all of which were universally glowing. Below are some highlighted, completely unedited responses we received:

"This guide is amazing, so many interesting facts about the company that I had no idea of. This guide made me really proud about the product. I have always used Dorman, and I have never had an issue with it. I was glad that I could learn some history about it. It was very interesting and fun to read.“ – mechanic from Mississippi

“I was not aware of all the products you had to offer. I was surprised that you had a dongle for steering racks and key fobs. I was very impressed. It gives me a whole new outlook on Dorman products. Keep up the great work.” – mechanic from Massachusetts

“I enjoy reading all the articles. I enjoy the electronic articles the most, but even enjoy reading articles about how Jack Dorman started the company making star washers. I always look forward to reading the next edition and learning more about Dorman advances.” – mechanic from Michigan

“Informative. Easy to read. Quirky writing style, not like a monotone instructor-ish delivery. Would/ will read again.” – mechanic from Pennsylvania

“Enjoyed reading it on my lunch break. A few parts even made me laugh.” – mechanic from New York

“It was a fun read. Usually the stuff I get from salesmen is boring. But this one wasn't! Thank you!” – mechanic from Iowa

“It was a great read. As a 40 year auto parts owner it is very difficult to get information to the rank and file and you do a great job.” – parts store professional from Michigan

“The verbiage of the articles was very nice and easy to read/understand. Seemed very ‘with the times’ which I especially liked. Great mentions & features on the products. Just learned about OE FIX & will definitely be checking out the older volumes!” - mechanic from Colorado

“I particularly enjoyed the article on Dorman’s windshield wiper linkage/transmissions and how you developed a quality solution by taking a look at an OEM GM and or BMW design and improved upon it. I’m becoming a brand loyal purchaser as your company’s reputation is evident time and time again. This takes me to last week, whereas I had a client that needed a replacement thermostat in their Chevy Cruise. Now, they specifically wanted to order the original GM parts and I understand as General Motors and AC Delco, are industry leaders but, I discovered Dorman made this part better (as per countless reviews) with the best quality and for half the price! I certainly felt confident in purchase ordering the Dorman brand over the faulty GM one which had failure in the seals. Of course describing the improved quality Dorman product was clearly the easiest suggestion and sell point for the Chevrolet Cruise owner, better quality-more savings!” - mechanic from Michigan

Volumes 3 and 4 also won back-to-back Automotive Communications Awards from the Auto Care Association, the leading trade organization for the automotive aftermarket, for best print publication. In a way, this was even greater validation than the CMI award, because it showed leadership that we were clearly the leaders in our space.

Shortly before I left Dorman our team had just finished OE FIX Guide Vol. 5. By then we had expanded the format from 24 to 32 pages, changed from gloss to a matte finish to give it a more premium tactile experience, and optimized distribution further to reach nearly every single auto repair shop in America. We accomplished all of that while streamlining production dramatically at a total project cost that was still approximately half what it was five years prior.

Achieving all this was not easy. Our team had to win over many senior leaders that auto repair professionals would actually read longer-form content. Changing the way we distributed the guide meant reducing quantities for some stakeholders, which was met with initial resistance. Creating articles that truly resonated with wrenchers required using a unique tone and in-crowd slang that raised some eyebrows from our legal and compliance teams. Sometimes the behind-the-scenes discussions to get new ideas approved from leadership required just as much work and discussions as the content creation itself.

In the end, the OE FIX Guide became Dorman’s flagship marketing effort, which was most instrumental in changing minds about what the Dorman brand stood for, driving incremental sales of the products featured in the publication, as well as creating a halo effect for the entire 80,000-product portfolio.

To see all five editions of the guide, visit the publications page of Dorman’s website here.